|

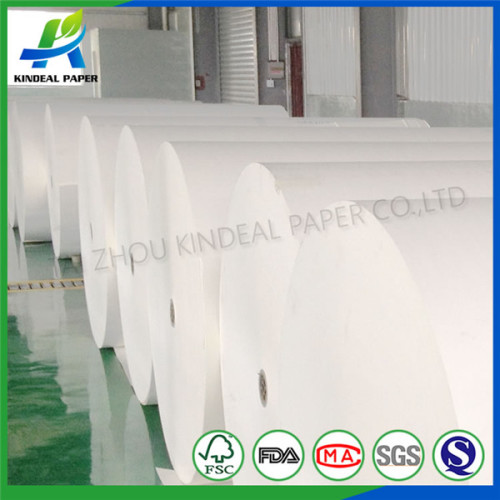

Taizhou Kindeal Paper CO., LTD.

|

| Price: | 1300.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Advantage

1.Doing pe coating since 1997 year

Our factory doing PE coating since 1997 year.We have well trained and sufficient Technicians will provide excellent and quality service.

2.PE coating's smoothness and uniform is promised.

Four PE lamination machines all control by automatic man-machine interface operation, precise calculation of extrusion thickness automatically by a computer.

3.Virgin paper as raw material with high content of Hardwood pulp.

The Hardwood pulp content is higher than common paper on market ensured high stiffness and folding strength of paper cup paper. This also can reduce failure rate of paper cup forming.

4.More than 10 years printing experience.

Starting from 2003, our factory doing paper printing for paper cup, paper meal box, paper lids, paper plate etc. We special high salary invited 5 experienced printing technicians. Every master in is trained strictly with decades of printing experience.

Semi-finsiehd paper plates

We offer service of printing and cutting into round shape for paper plate. At max can do 6 color printing.

Recommended Paper for paper plates:

White card paperboard

Food grade cup paper

Food grade clay coated paper

Food grade noodle board paper

Food grade pe coated cup paper

Food grade pe + clay coated paper

Food grade Pe coated noodle board paper

semi-finished printed and cutted paper plates | |

Material | 150gsm~350gsm Paper+ PE(12gsm~26gsm) |

Printing | Flexo printing / Offset printing |

Usage | Paper plate |

Quality level | KD1-CB KD2-CB KD3-CB KD1-NB Whiteboard |

Packing way | In cartons packing In plastic bag packing |

Loading | 1*20gp can load: around 15~16 tons semi-finished paper plate 1*40gp can load: around 25 tons semi-finished paper plate |

Lead time | Around 30 days after receive deposit |

| 1. PE coating Uploading raw material paper on PE coating machine. PE melted in high temperature machine then evenly coating on raw material paper surface. |

| 2.paper plates paper printing Recommend using flexo pritning for round plate printing in order to reduce the wastage. |

| 3. Clean the wastage to get semi-finished printed and cutted paper plates |

We Can Supply: